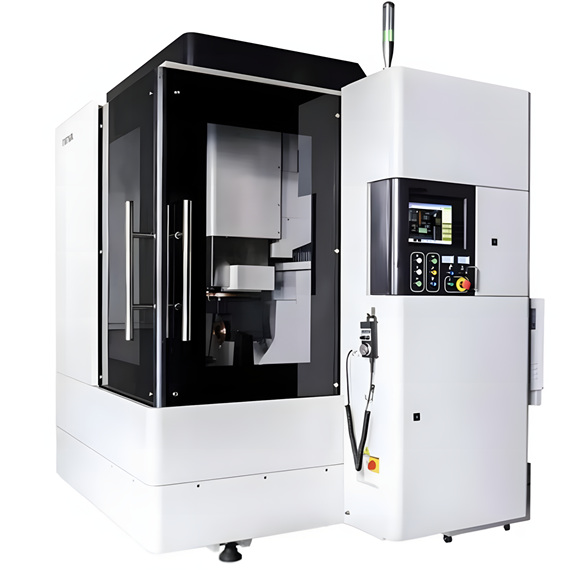

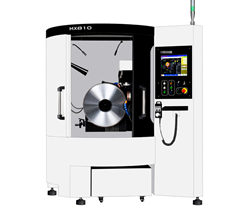

The MD43Plus EDM Tool Grinding Machine is a state-of-the-art CNC system engineered for high-precision grinding of PCD (Polycrystalline Diamond), carbide, and complex spiral tools. Equipped with five servo axes (X, Y, Z, A, C) and advanced discharge technology, it delivers exceptional accuracy, efficiency, and consistency—making it the ideal choice for tool manufacturers, aerospace, automotive, and precision engineering industries.

Key Features

1. High Precision & Multi-Axis Control

5-Axis CNC Linkage – X, Y, Z linear axes + A (indexing) and C (rotation) rotary axes for complex tool geometries.

Sub-Micron Accuracy – Linear axis control: 0.001 mm; indexing axis: 0.001°.

High Repeatability – Run-out accuracy as low as 0.02 mm for consistent tool quality.

2. Advanced EDM Technology

Ultra-Fine PCD Pulse Circuit – Equipped with energy-equalizing pulse control for stable discharge and superior edge quality.

Automatic Gap Adjustment – Real-time discharge monitoring and adaptive feed control to maintain optimal grinding conditions.

Electrode Auto-Turning – On-machine electrode dressing and compensation for extended tool life and accuracy.

3. Intelligent Software & Automation

Fill-in-the-Blank Programming – User-friendly interface with pre-loaded tool libraries; no coding required.

Automatic Spiral Detection – Built-in software for automatic helix measurement and multi-tooth tool processing.

One-Cycle Automation – Complete roughing to finishing in a single setup, ensuring consistency and reducing operator intervention.

4. Robust Mechanical Design

High-Rigidity Cast Structure – Manufactured from high-grade nodular cast iron for vibration damping and long-term stability.

Precision Linear Guides & Ball Screws – Imported linear rails and pre-stretched ball screws ensure smooth motion and thermal stability.

AC Servo Spindle Drive – Stepless speed control (forward/reverse) for flexible grinding operations.

5. Safety & Reliability

Full Enclosure & Safety Systems – Integrated photosensitive protection and automatic fire suppression.

International Standard Components – All electrical and hydraulic parts comply with global quality norms.

Low-Noise Italian Oil Pump – Ensures quiet and reliable fluid circulation.

Applications of MD43Plus EDM tools grinding machine

PCD & CVD Tool Grinding – End mills, drills, reamers, inserts

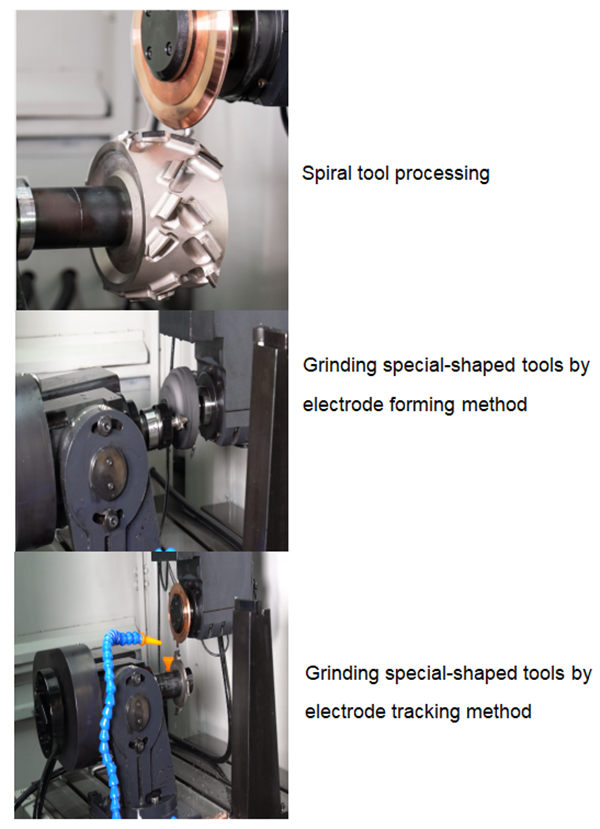

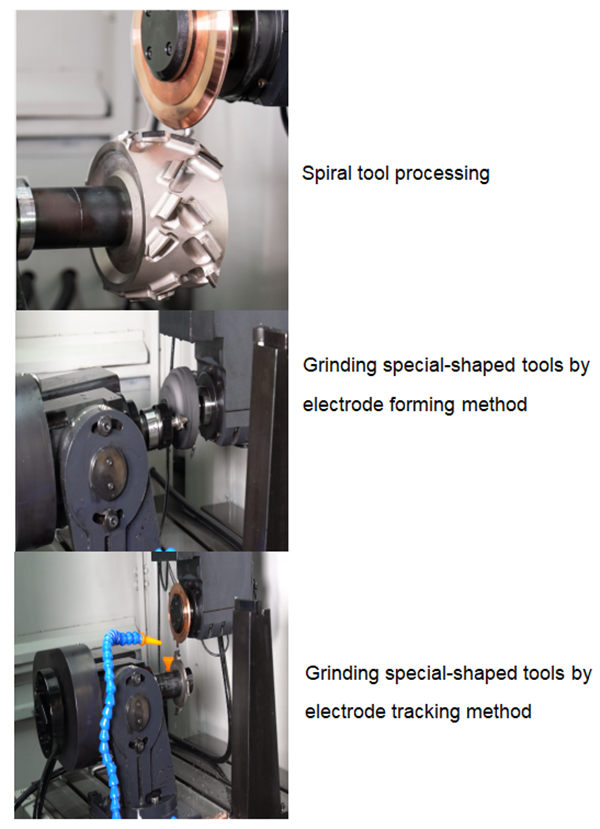

Spiral & Helical Tools – Diamond spiral cutters, thread mills, form tools

Carbide Tool Sharpening – Router bits, milling cutters, engraving tools

Special-Shaped Tool Processing – Via electrode forming or trajectory tracking methods